Application:

PIPE

Plastic Processed:

PE, PP, PVC

Condition:

New

Screw Design:

Single-screw

Screw Material:

38CrMoALA

Screw Diameter (mm):

65

Screw L/D Ratio:

33:1

Screw Speed (rpm):

37 Rpm

Showroom Location:

Turkey, Peru, Saudi Arabia, Indonesia, Pakistan, Kenya, Argentina, Colombia, Sri Lanka, Bangladesh, Malaysia

Voltage:

220V/380V/440V

Dimension(L*W*H):

20*2*3m

Power (kW):

100

Weight:

10-20T

Warranty:

1 Years

Key Selling Points:

Multifunctional

Applicable Industries:

Manufacturing Plant

Marketing Type:

New Product 2020

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC, Gearbox, Screw

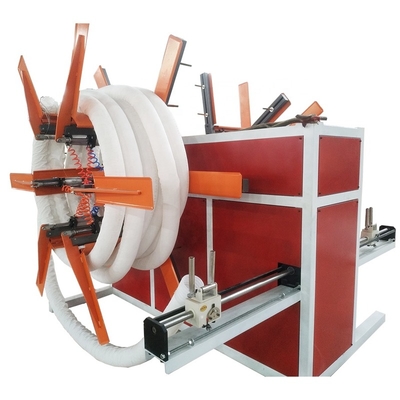

Name:

PE PP PVC Corrugated Pipe Extrusion Machine

Motor:

SIEMENS Brand

Inverter:

ABB Brand

Temperature Control:

Ormon Brand

Contactor:

SIEMENS Brand Or Schneider Brand

PLC:

SIEMENS Brand

Raw Material Of Pipe:

PE PP PVC Resin

Usage:

Produce Corrugated Pipe

Color:

According To Customers' Require

Other Name:

PE PP PVC Single Wall Corrugated Pipe Making Machine

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, Canada, Turkey, United Kingdom, United States, Italy, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile,

Certification:

CE